Editor’s note: As a first on this blog, I have asked Jurgen Hulst, a colleague for which I have tremendous respect, to write a guest post on coordination of logistics. Jurgen started in 2000 with humanitarian work in South America. Since then he has been doing various work always with a health logistics focus in several humanitarian emergencies worldwide. In 2005 he made the switch from an NGO to logistics work at a big UN agency. He is currently active in supply chain improvement and emergency logistics coordination, through the cluster approach. Jurgen can be found on Twitter as @NFIGuy.

The private sector acknowledged that creating partner networks to improve collaboration can improve supply chain efficiency and save millions. The United Nations, mindful that a collective effort could strengthen a humanitarian response in emergencies, in 1991 established OCHA to improve coordination.

Easier said than done. Do you need to be coordinated?

Right, until 2005 it was business as usual, until an independent review identified long-standing gaps: weak partnerships and insufficient accountability.

As a result in 2005 the IASC, a “unique forum involving the key UN and non-UN humanitarian partners”, started the Humanitarian Reform, using the cluster approach as a new, improved, way of creating partnerships and improving collaboration.

What does this mean for logistics during a humanitarian emergency? It means that in recent new emergencies such as in Pakistan and Gaza and in ongoing humanitarian crises, a Logistics Cluster, supported by WFP, can provide a platform for local and international NGO’s, government and UN agencies to improve logistics collaboration; and consequently improve the overall humanitarian response.

If you are actively involved in logistics in a humanitarian crisis:

- Visit http://www.logcluster.org/ to find out if your country has a Logistics Cluster. If so, this site will be good source for up to date maps, road, air, sea transport and contact information. If not, it is still a useful resource for Logistics toolkits & links.

- Participate in the next local Logistics Cluster meeting, because you can meet colleagues and find solutions for customs issues, increased transport prices and shortages of warehouse space, to name a few frequent problems.

- Participate even if your organisation has well established operations, because your knowledge can help newcomers, while others agencies may offer supplies and services which you can use immediately.

- Turn to WFP as a ‘provider of last resort’ for logistics. This means that WFP, as the lead agency for Logistics, accepted the commitment to do their utmost to fill critical gaps in the logistics operations during a humanitarian response.

Logistics and supply chain management in the private sector evolved from doing it yourself, to outsourcing parts of it (third party logistics or 3PL), into using companies which provide integrated supply chain solutions (fourth party logistics or 4PL).

Similar to 4PL the Logistics Cluster provides a unique opportunity for the humanitarian community to share assets and competencies, in order to reach integrated solutions. However, contrary to 4PL, a Logistics Cluster or lead agency does not attempt to run logistics operations on behalf of your organisation.

Does it work, or is it just another talk shop? I invite commenters to provide their own experiences.

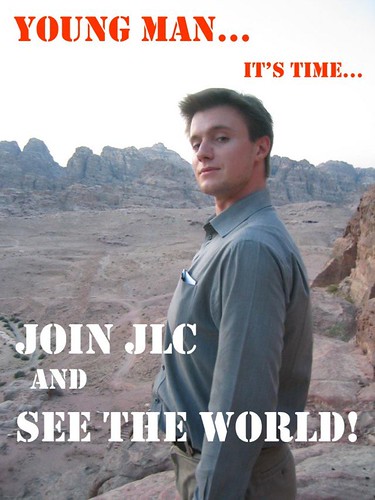

(Image: UN JLC recruitment poster by Nigelito @ flickr)

{